The promise of a personal hot tub a private sanctuary of warm, therapeutic relaxation is compelling. However, before you can enjoy that first peaceful soak, there’s a critical phase that demands absolute precision and expertise: hot tub wiring. As a master electrician who has overseen hundreds of spa installations over three decades, I can tell you unequivocally that the electrical work is where safety is won or catastrophically lost. This isn’t a project where “close enough” suffices. Every connection, every wire gauge selection, every placement decision must meet exacting standards. This guide provides you with the comprehensive framework to understand what proper hot tub electrical installation entails, from the main service panel to the final termination point at your spa.

Whether you’re planning to hire a professional or simply want to understand the scope of work involved in how to wire a hot tub, this manual will equip you with the technical knowledge necessary to ensure your installation is executed flawlessly. We’ll explore everything from interpreting local electrical codes to selecting the precise copper wire gauge for your specific amperage requirements, ensuring that your investment delivers years of safe, worry-free enjoyment.

Table of Contents

1. Understanding the Core Electrical Principles of Hot Tub Wiring

A hot tub is not a typical household appliance. Unlike a toaster or television that draws modest power intermittently, your spa is a major electrical load that operates continuously for hours, combining the demands of a powerful heater (typically 4,000-6,000 watts), circulation pumps, jet pumps, and sophisticated control systems. To put this in perspective, the electrical requirements rival those of a central air conditioning unit or an electric oven appliances that electricians treat with appropriate respect and caution.

The combined amperage draw of these systems under full operation can range from 30 to 60 amperes at 240 volts. This sustained, heavy load is precisely why dedicated circuits, properly sized conductors, and specific wiring methods aren’t optional considerations they’re absolute requirements dictated by electrical safety science and codified in law. Attempting to power a hot tub from a standard household circuit would be like trying to fill a swimming pool through a garden hose connected to a kitchen faucet: fundamentally inadequate and structurally dangerous.

Before diving into hot tub games, ensure your spa water chemistry is properly balanced for safe and comfortable play.

1.1. Why Do Hot Tubs Need Special Wiring?

The power demands of modern hot tubs are substantial and non-negotiable. A typical residential spa operates at 240 volts and draws between 40 and 60 amperes of current. To understand why this matters, consider that a standard household outlet provides 120 volts at 15 or 20 amperes maximum. Attempting to power a 240V, 50-amp hot tub from such a circuit wouldn’t just trip the breaker it would create an immediate fire hazard as the undersized wiring overheated under a load it was never designed to handle. The National Fire Protection Association reports that electrical distribution equipment is a leading cause of home structure fires, and improper wiring of major appliances is a significant contributing factor.

1.2. The Critical Role of the National Electrical Code (NEC)

The National Electrical Code, published by the National Fire Protection Association (NFPA), serves as the foundational benchmark for electrical safety throughout the United States. NEC Article 680: Swimming Pools, Fountains, and Similar Installations specifically governs hot tub and spa wiring. This article exists because water and electricity create uniquely dangerous conditions the human body’s electrical resistance drops dramatically when wet, making even small voltage leakages potentially fatal.

Article 680 mandates specific requirements for grounding, bonding, GFCI protection, and minimum clearances that go far beyond standard electrical work. Critically, while the NEC establishes minimum national standards, your local jurisdiction may adopt amendments or additions. Before beginning any work, you must consult your local building department to understand the specific code requirements in your area [link to future article on local electrical codes].

1.3. Voltage and Amperage Demystified

Hot tubs generally fall into two categories: 120-volt “plug-and-play” models and 240-volt hard-wired installations. The 120V units are smaller, portable spas designed to plug into a standard 20-amp outlet. While convenient, they sacrifice heating power and jet performance. This guide focuses on the more common and substantially more complex 240-volt hot tub electrical wiring installations that deliver the full spa experience.

Understanding amperage is essential: it represents the volume of electrical current flowing through the circuit. A 50-amp circuit can safely deliver 50 amperes of current continuously. Your hot tub’s specifications will indicate its amperage requirement, typically ranging from 40 to 60 amps for residential models. The circuit, breaker, wire gauge, and disconnect must all be rated to match or exceed this requirement with appropriate safety margins.

2. Essential Components for Your Hot Tub Electrical Installation

Professional jacuzzi electrical wiring requires specific components, each serving a critical safety function. Understanding these elements and their roles is fundamental to appreciating the complexity and importance of proper installation. Every component must meet NEC specifications and be appropriately rated for the electrical load.

For families seeking spacious hydrotherapy options, exploring the features of a 7 person hot tub can help you determine if this size fits your entertaining and wellness needs.

2.1. The GFCI Disconnect Panel

The Ground Fault Circuit Interrupter (GFCI) disconnect panel is the single most important safety device in your hot tub electrical system it is literally a life-saving component. A GFCI continuously monitors the current flowing through the hot and neutral conductors. If it detects even a tiny imbalance (typically 4-6 milliamperes), indicating that current is leaking through an unintended path potentially through a person in contact with water it trips instantly, cutting power in as little as 1/40th of a second.

NEC Article 680.42 mandates GFCI protection for all hot tubs and spas. Additionally, the disconnect function allows you to completely isolate power to the spa for maintenance or emergency situations. Code requires this disconnect to be located within line of sight of the hot tub you must be able to see the spa from the disconnect location but positioned no closer than 5 feet from the water’s edge. Many jurisdictions also specify a maximum distance of 50 feet. This placement ensures you can quickly cut power in an emergency while maintaining safe clearance from the water [link to future article on GFCI requirements].

2.2. Selecting the Correct Hot Tub Wire Size

Hot tub wire size selection is perhaps the most technical decision in the installation process, and getting it wrong has serious consequences. Wire gauge, measured in American Wire Gauge (AWG), must be determined based on two critical factors: the amperage rating of the circuit and the total length of the wire run from your main panel to the hot tub. Undersized wire creates resistance, generates dangerous heat, and can cause voltage drops that damage your spa’s components or create fire hazards.

The table below provides general guidelines for copper wire sizing, which is standard for hot tub installations:

| Circuit Amperage | Copper Wire Size (AWG) for up to 100 ft |

| 30 Amps | 10 AWG |

| 40 Amps | 8 AWG |

| 50 Amps | 6 AWG |

| 60 Amps | 6 AWG (or 4 AWG for longer runs) |

Critical Note: This table represents general guidance only. Wire sizing must account for ambient temperature, conduit fill, and specific run distances. For runs exceeding 100 feet, you must upsize the conductors to compensate for voltage drop typically one gauge size larger for every additional 50 feet. Always consult NEC Chapter 9, Table 8 for conductor properties and your hot tub manufacturer’s specifications. When in doubt, oversizing wire is always safer than undersizing. Never use aluminum wiring for hot tub installations unless specifically approved by your local code and manufacturer the connection integrity issues and expansion/contraction properties of aluminum create unacceptable risks in this application.

If you’re unsure how much room you need, our article on 6 person hot tub dimensions breaks down all the measurements in detail.

2.3. Does Hot Tub Wiring Need to be in Conduit?

The answer is an unequivocal yes. Wiring hot tub circuits without conduit is a code violation and an invitation to disaster. Conduit serves multiple essential functions: it provides mechanical protection against physical damage from digging, landscaping, or structural settling; it shields the conductors from moisture infiltration; and it protects against UV degradation, rodent damage, and corrosion. NEC Article 680.42(A) specifically requires that spa and hot tub circuits be installed in approved raceways conduit being the most common type.

You’ll encounter two primary categories of conduit:

Metallic Conduit (Rigid Metal Conduit/RMC or Intermediate Metal Conduit/IMC): These provide superior physical protection and are required in areas where the installation is exposed to potential impact or mechanical damage. RMC is typically used for above-ground runs along building exteriors or in areas subject to vehicle traffic.

Non-Metallic Conduit (PVC Schedule 40 or Schedule 80): PVC conduit is the standard choice for direct burial applications and areas protected from physical damage. Schedule 40 is adequate for most residential underground runs, while Schedule 80 offers thicker walls for situations requiring extra protection. PVC is corrosion-proof, cost-effective, and easier to work with than metallic alternatives, making it the preferred choice for trenched installations.

All conduit runs must be properly sized to prevent overcrowding of conductors (NEC Chapter 9, Table 1), and all fittings, connectors, and terminations must be appropriate for wet locations and rated for the environment in which they’re installed.

3. The Step-by-Step Process of Wiring a Hot Tub

CRITICAL SAFETY DISCLAIMER: The following section is provided strictly for educational purposes to help you understand the scope, sequence, and complexity of professional hot tub electrical installation. Under no circumstances should unlicensed individuals attempt to perform this work. Electrical installations at this voltage and amperage level pose severe risks of electrocution, fire, property damage, and death. All work must be performed by a qualified, licensed electrician who carries appropriate liability insurance and is familiar with local code requirements. Improper installation will void your hot tub warranty, violate building codes, fail inspection, and may result in your homeowner’s insurance denying claims related to electrical damage or injury.

Choosing the right gauge and type of 40 amp hot tub wire is fundamental to the efficient and safe operation of your spa.

3.1. Planning the Route and Trenching

Professional installation begins with careful planning of the most direct, practical route from your home’s main electrical panel to the GFCI disconnect location, and then from the disconnect to the hot tub’s control panel. The electrician will survey the property to identify obstacles existing underground utilities, sprinkler lines, tree roots, concrete, and hardscaping that affect the route. Many jurisdictions require calling 811 (the national “Call Before You Dig” hotline) at least 48-72 hours before excavation to have underground utilities marked.

Does Hot Tub Wiring Need to be Buried?

For outdoor hot tub installations, the answer is typically yes, unless you’re running the circuit through an existing basement, crawlspace, or along an exterior wall using approved conduit mounting. When burial is required, NEC Article 300.5 establishes minimum depth requirements based on the type of conduit and installation method:

- PVC Conduit (Schedule 40/80): 18 inches minimum depth below grade

- Rigid Metal Conduit (RMC): 6 inches minimum depth below grade

- Underground Feeder Cable (UF) without conduit: 24 inches minimum depth (though conduit is strongly preferred)

Local codes may mandate greater depths, particularly in areas with deep frost penetration or heavy vehicle traffic. The trench width should allow at least 2-3 inches of clearance on all sides of the conduit for proper bedding with sand or fine soil. Sharp rocks must be removed to prevent conduit damage. Many professionals install warning tape 6-12 inches above the conduit as an additional safety measure for future excavations.

3.2. The Main Breaker Panel Connection

The installation begins at your home’s main electrical service panel, where a dedicated 240-volt double-pole circuit breaker is installed. This breaker must be sized exactly to the circuit requirements a 50-amp circuit requires a 50-amp breaker, a 60-amp circuit requires a 60-amp breaker. This is not a situation where “bigger is safer”; an oversized breaker won’t trip when it should, allowing wiring to overheat.

Explore this related topic as well: how 0 hot tub financing works and what to watch out for.

The electrician will install the breaker in an available space in the panel, connecting it to both hot bus bars (providing the 240 volts). The circuit requires four conductors: two hot wires (typically black and red), one neutral wire (white), and one equipment grounding conductor (green or bare copper). The two hot wires connect to the breaker terminals. The neutral wire connects to the neutral bus bar (usually silver in color), and the ground wire connects to the grounding bus bar (often green or with exposed copper).

This is exacting work. Connections must be torqued to manufacturer specifications too loose and they’ll arc and overheat; too tight and you risk damaging the conductor or terminal. Every connection must be verified before the panel cover is replaced. One loose connection can create a cascading failure that destroys equipment or starts a fire.

3.3. Wiring the GFCI Disconnect

The GFCI disconnect panel is the critical intermediary between your main panel and the hot tub. Understanding the line/load concept is essential to proper installation. The disconnect has two sets of terminals clearly marked:

LINE terminals: These receive power from the main panel. The two hot wires, neutral, and ground from your main panel breaker connect here. This is the power source feeding the GFCI.

LOAD terminals: These supply power to the hot tub. The two hot wires, neutral, and ground running to your spa connect here. The GFCI monitors and protects this outgoing power.

Reversing these connections connecting the main panel to the load side or the hot tub to the line side renders the GFCI non-functional. The spa would operate, but without any ground fault protection, creating a deadly hazard. This is why professional installation is critical; it’s a mistake that a layperson might not realize they’ve made until it’s too late.

The disconnect must be mounted securely in a weatherproof enclosure rated for wet locations (NEMA 3R minimum for outdoor installations). It should be positioned at a comfortable working height (typically 48-60 inches from grade to the center of the disconnect) and mounted to a solid surface or post that won’t shift or settle.

3.4. The Final Connection to the Hot Tub

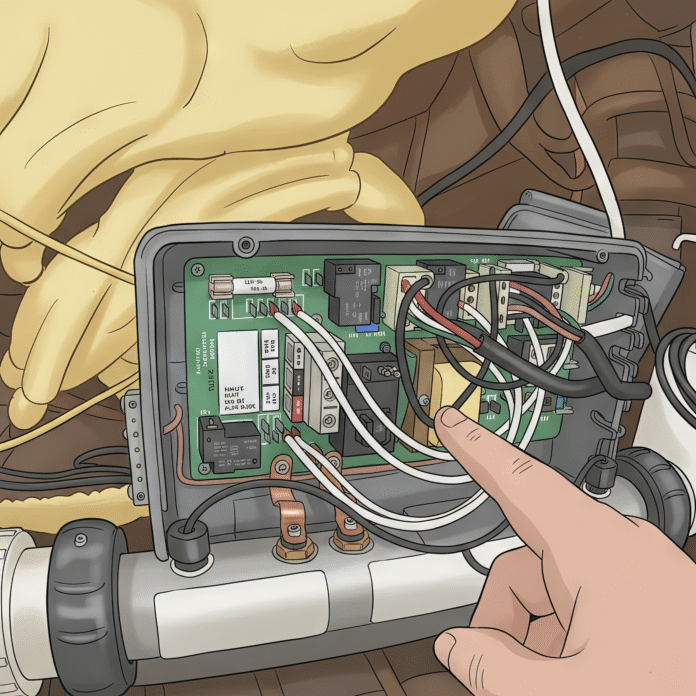

The final stage involves running conduit and conductors from the GFCI disconnect to the hot tub’s control panel. The conduit terminates at a weatherproof connector that enters the spa’s equipment compartment. Here, the hot tub wiring diagram provided by the manufacturer becomes indispensable. Unlike standardized household wiring, hot tub terminal configurations vary significantly by make and model. The diagram shows exactly where each conductor must be connected within the control box.

Typically, the two hot wires connect to terminals marked L1 and L2 (or Line 1 and Line 2). The neutral connects to a terminal marked N or Neutral. The ground wire connects to the ground bus or terminal, which is also bonded to the spa’s metal frame and equipment. Some installations also require bonding to a metal grounding grid or perimeter bonding conductor surrounding the spa.

Before making these final connections, the electrician will verify that power is disconnected at the main panel and the GFCI disconnect is in the OFF position. After connections are complete, they’ll meticulously verify each one, checking for proper tightness and correct placement. Only then and only after inspection approval will power be energized for the first time.

4. Safety, Permits, and Professional Installation

The technical complexity we’ve outlined makes one thing abundantly clear: proper hot tub electrical installation demands expertise, experience, and accountability. Let me address this directly from decades of professional experience.

4.1. Do It Yourself Hot Tub Wiring: A Word of Caution

I am frequently asked whether homeowners can perform their own hot tub electrical work. My answer is unambiguous: unless you are a licensed electrician with specific training in NEC Article 680 requirements, you should not attempt this work. Here’s why this isn’t merely professional protectionism it’s about genuine safety and liability:

Safety Risks: Working in your main panel with 240-volt circuits is inherently dangerous. Even with the main breaker off, utility feed wires remain energized at full voltage. Contact with these conductors is often fatal. Beyond the installation phase, improper wiring creates ongoing hazards: fire from overheated connections, electrocution from inadequate grounding or missing GFCI protection, and equipment damage from incorrect connections or voltage issues.

Code Violations and Failed Inspections: Unpermitted DIY electrical work violates building codes in virtually every jurisdiction. When discovered during a home sale inspection, after an insurance claim, or following an incident you’ll be required to bring the installation into compliance at your expense. More concerning, electrical work that fails inspection must be redone, potentially requiring removal of concrete, landscaping, or decking to access buried conduit.

Warranty Voidance: Every reputable hot tub manufacturer requires that electrical installation be performed by a licensed electrician. DIY work immediately voids your warranty. When a $10,000 spa fails due to electrical issues and the manufacturer discovers unlicensed installation, you’ll be absorbing the full replacement cost.

Insurance Implications: Homeowner’s insurance policies often contain exclusions for damage or injury resulting from unpermitted, unlicensed work. A house fire traced to DIY hot tub wiring could result in a denied claim, leaving you personally liable for hundreds of thousands in damages.

The few hundred dollars saved by avoiding professional installation is a reckless gamble against costs that could financially devastate a family.

4.2. The Permitting and Inspection Process

Most jurisdictions classify hot tub electrical installation as major electrical work requiring a permit. The process typically follows this sequence:

- Permit Application: Your electrician submits a permit application to the local building department, including a site plan showing the circuit route, equipment locations, and specifications for all components. Some jurisdictions require this in advance; others allow same-day permits.

- Installation: The electrician performs the work according to code and approved plans. They may request an inspection at multiple stages after trenching but before backfilling, after main panel work, and before final connection.

- Inspection: A local electrical inspector reviews the installation to verify code compliance. They’ll check wire sizing, conduit installation, burial depth, GFCI operation, grounding and bonding, clearances, and main panel connections.

- Approval and Energization: Only after the inspector approves the installation and issues a final sign-off can the circuit be permanently energized and the hot tub operated.

This process isn’t bureaucratic inconvenience it’s a critical safety verification performed by a third-party expert with no financial stake in the outcome. It protects you, your family, and future property owners.

4.3. How to Hire a Qualified Electrician

Not all licensed electricians have experience with NEC Article 680 installations. When hiring a professional, follow these guidelines:

Verify Licensing: Confirm that the electrician holds a current master or journeyman license in your state. Many states have online license verification portals. Don’t accept verbal assurances verify independently.

Confirm Insurance: Request proof of current liability insurance and workers’ compensation coverage. If an uninsured worker is injured on your property, you may be held liable.

Request References: Ask for references from recent pool or hot tub installations. Contact these references and ask specific questions about work quality, timeline, and problem resolution.

Get Detailed Quotes: Obtain written quotes from multiple electricians. The quote should itemize materials, labor, permit fees, and inspection costs. Be wary of quotes significantly below market rate they often indicate cut corners or hidden fees.

Discuss Timeline: Understand the realistic timeline for permitting, installation, and inspection. Quality work takes time; a rush job increases error risk.

The relationship between cost and quality in electrical work is direct. This isn’t an area to search for bargains. A professional installation performed to the highest standards is an investment in safety, reliability, and peace of mind.

Conclusion

Proper hot tub wiring represents the intersection of electrical engineering, practical craftsmanship, and unwavering commitment to safety. As we’ve explored throughout this guide, a compliant installation requires a dedicated 240-volt circuit with correctly sized conductors (typically 6 AWG for 50-amp circuits), weatherproof conduit protecting all wiring, proper burial depths or protected routing, a properly located GFCI disconnect panel providing life-saving ground fault protection, and precise connections at the main panel, disconnect, and spa control box all verified through professional inspection.

The electrical infrastructure supporting your hot tub is not merely a functional requirement to make the pumps run and the water heat. It is a carefully engineered safety system designed to protect you, your family, and your property from the inherent dangers of combining water with high-voltage electricity. Every component, every specification, every code requirement exists because of hard lessons learned through decades of electrical accidents and extensive safety research.

Your hot tub represents a significant investment in your home and quality of life typically $5,000 to $15,000 or more for the spa itself. Protecting that investment with a professional electrical installation costing $1,000 to $2,500 is not an expense; it’s essential insurance. More importantly, it’s an investment in the safety of everyone who will use your spa for years to come. There is no acceptable compromise on hot tub electrical installation. Invest in licensed professionals, obtain proper permits, insist on inspection approval, and enjoy the peace of mind that comes from knowing your backyard oasis is as safe as it is relaxing.

Frequently Asked Questions (FAQ)

What is the average cost for a professional hot tub electrical installation?

Professional hot tub electrical installation typically ranges from $800 to $2,500, with most homeowners paying $1,200 to $1,800 for a standard installation. This cost variance depends on several factors: the distance from your main electrical panel to the hot tub location (longer runs require more materials and labor), the complexity of the route (direct trenching versus navigating around obstacles, running under driveways, or routing through crawlspaces), whether the main panel has adequate capacity and available breaker spaces (panel upgrades add $1,500-$3,000), local labor rates (urban areas typically command higher rates than rural locations), and permit and inspection fees (typically $100-$300). A straightforward 40-foot run with minimal obstacles will be on the lower end, while a 100-foot run requiring extensive trenching, concrete cutting, or panel upgrades will approach or exceed the higher end. Always obtain detailed written quotes from multiple licensed electricians.

Can I use an extension cord for my 240V hot tub?

Absolutely not, under any circumstances. This question, while common, reflects a fundamental misunderstanding of the electrical loads involved. Standard extension cords even heavy-duty models are not rated for the 40-60 amp continuous loads that hot tubs draw. The wire gauge is insufficient, the insulation is inadequate for permanent outdoor use, the connections aren’t waterproof, and crucially, there’s no GFCI protection. Attempting to operate a 240V hot tub on an extension cord will result in extreme heat buildup in the cord, melting insulation, potential fire, and severe shock hazard if the deteriorating insulation allows water contact with conductors. This practice violates all electrical codes and will immediately void your hot tub warranty. Hot tubs must be permanently wired through properly sized, conduit-protected circuits with GFCI protection. There are no exceptions, and there is no “temporary” alternative that is safe.

What’s the difference between a hot tub wiring diagram and a general electrical schematic?

A general electrical schematic shows the overall circuit architecture the path from your home’s main service panel, through the breaker, to the GFCI disconnect, and finally to the hot tub. It illustrates the system at a conceptual level: how the various components interconnect, the wire gauges, the voltages, and the protective devices. This schematic helps you understand the complete electrical system serving your spa.

In contrast, the hot tub wiring diagram is a specific document provided by your spa manufacturer for your exact make and model. It shows the precise internal wiring of your hot tub’s control system, identifying the exact terminals where you must connect the incoming power supply. These terminals typically marked L1, L2, N (neutral), and G (ground) may be configured differently across manufacturers and models. The wiring diagram also shows how the internal components (heater, pumps, lights, control board) are connected within the spa, though the installer typically doesn’t modify these factory connections. This diagram is absolutely critical during the final connection phase. Connecting power without referencing this diagram can result in reversed polarity, damaged components, or dangerous operating conditions. Both documents are essential: the schematic for planning and installing the circuit, and the wiring diagram for making the final, correct connections to your specific hot tub.

Resources

- National Electrical Code (NEC) – National Fire Protection Association (NFPA): https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=70

- Electrical Safety Foundation International (ESFI): https://www.esfi.org

This guide is provided for informational and educational purposes only. All electrical work must be performed by licensed professionals in accordance with national and local electrical codes. The author and publisher assume no liability for injuries, damages, or code violations resulting from improper installation or interpretation of this information.